The concept of printing has altered with the introduction of 3D technology, as it has altered how the products are manufactured, designed, and prototyped. With 3D printing, intricate structures can be created and customized layer by layer, ultimately creating a delicate digital design. 3D printing has made significant progress since its inception in the printing market, and various industries have gained significant advantages from it. For instance, platforms like Vulkan Vegas have incorporated online slot machines whose themes are based on 3D designs. At the same time, multiple sectors have incorporated the innovations via 3D innovations.

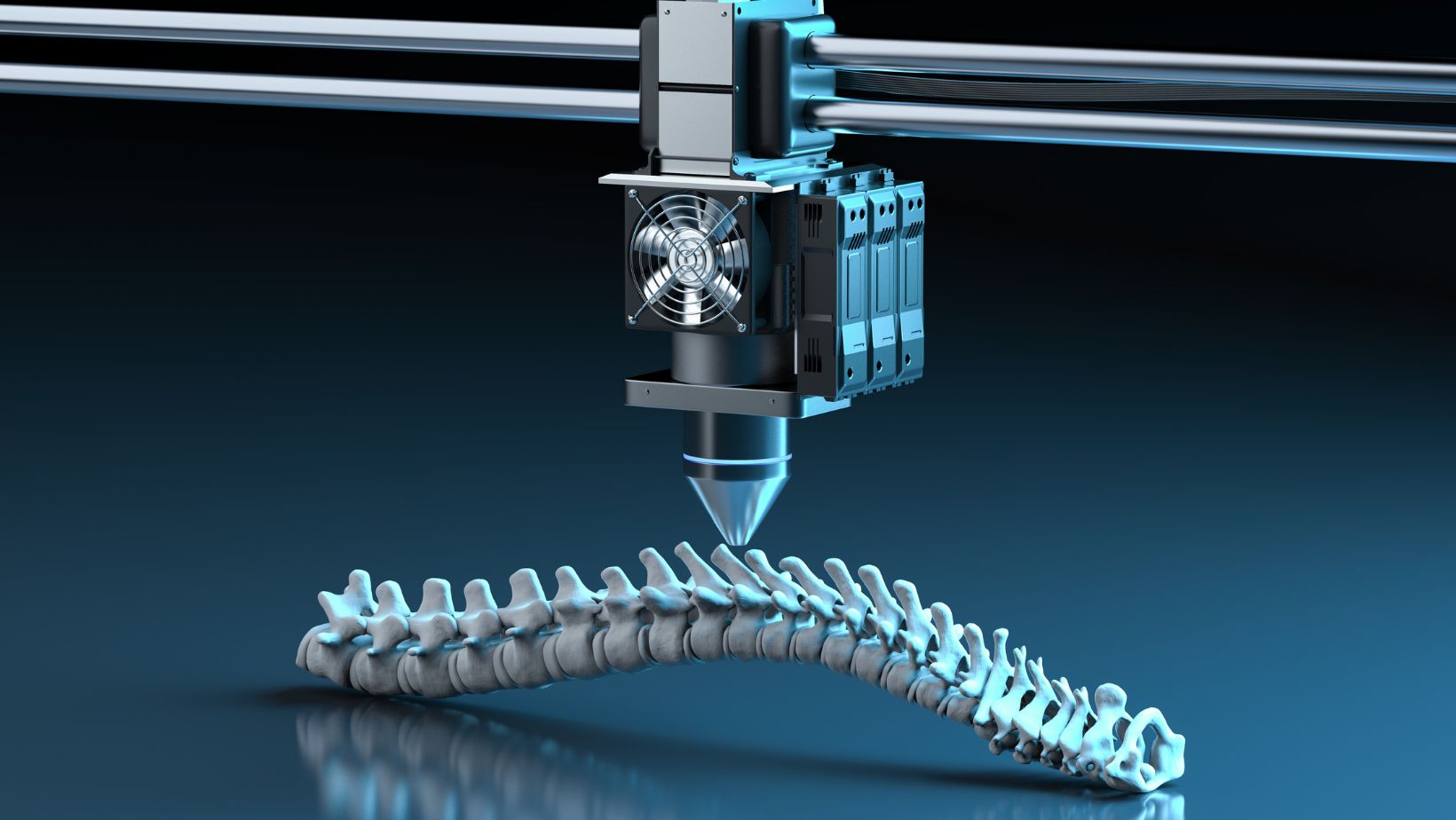

Healthcare and Medicine

In the field of healthcare and medicines, 3D printing has left remarkable impacts and has provided the services as follows:

- Plastic surgery and medical devices. In healthcare and cosmetic surgery, 3D printing has proved revolutionary. It has facilitated the creation of customized medicinal devices and conducted plastic surgery according to individuals’ needs. Moreover, the 3D prosthetic procedure proves highly effective and efficient compared to the traditional ones because it requires multiple fittings and alterations, whereas 3D is customized, allowing the professionals to develop the required element that is ultimately comfortable for the users.

- Bioengineering. Another revolutionary aspect of 3D technology is bioprinting, where the bio-links are used to culture the living cells and create tissue-like structures. Additionally, this technology is practical in imparting solutions such as organ transplants, and researchers are finding ways of printing human tissues and organs, which could replace the need for donors and would serve as an effective solution for dealing with the shortage of donors.

Defence and Aeronautical Solutions

3D printing is also serving its purpose in the aeronautical and defense industry in the following manner:

- Complex components development. 3D printing is highly industrious in the field of aerospace and defense systems, as it can develop complex components that are lightweight and could not be developed with traditional production techniques. Lightweight components are essential for reducing the weight of aircraft and, ultimately, improving their efficiency and performance.

- Quick work and performance. Unlike conventional production, 3D printing works quickly and rapidly, which enables engineers to check the designs swiftly. Ultimately, it speeds up the development process and reduces the waiting time and costs of the model. Moreover, 3D printing can conveniently generate spare parts for aircraft on demand, which reduces the expenses of developing huge inventories.

- Easy maintenance. 3D printing does not require huge inventories or setups. Therefore, it is an ideal solution to develop spare parts for aircraft in the remotest areas, thus reducing downtime. For military applications, 3D printing can produce spare parts in remote or combat areas, minimizing downtime and logistical challenges. This flexibility enhances the operational readiness and sustainability of military assets.

Automotive Industry

3D printing in the automotive industry enhances customization, efficiency, and lightweight design, improving vehicle performance and reducing maintenance costs:

- Personalization. In the automotive industry, 3D printing has also made significant strides, enabling prototyping and production. Additionally, the customization liberty lets manufacturers adapt and create distinctive designs, which boosts vehicle performance. The 3D design enables fast processing, thereby allowing the engineers to experiment with iteration effectively.

- Efficient designs. The 3D designs enable the production of efficient, lightweight designs that perform efficiently and consume less energy. This is especially true for electric vehicles, whose lightweight design has high performance and extends their battery life.

- Tooling. With the 3D prints, engineers can create smart tools for smart 3D design devices. Such tools effectively reduce maintenance time, leading to low management costs and accurate assembly of these devices.

Merchandise and Retailing

In the field of retailing, too, 3D designs provide several services, such as:

- Product customization. With 3D design technology, consumer goods are produced in less time and in massive quantities, enabling companies to meet customers’ needs in less time. Additionally, smart designs in different sectors, such as footwear, jewelry, and eyewear, are now customized on personalized devices. By providing customized designs, many companies have established brand loyalty and gained customers’ trust according to their needs.

- On-demand manufacturing. 3D design technology enables on-demand production and consumption, where manufacturers produce what consumers demand. This stops mass production and product wastage. It also enables sustainable practices and aids the manufacturer in meeting market demands faster and getting consumer feedback in less time.

- Innovative product development. The 3D print is flexible and integrates innovation, providing complex and detailed structure development that otherwise would be impossible to design traditionally. Therefore, it provides new horizons for product creation and development, creating a competitive market for developers and manufacturers.

3D printing is already in the market, and it has left a remarkable impact on the consumer market and created competition for manufacturers. So, whether it be aerospace technology, automotive systems, or manufacturing and retailing supply lines, 3D printing has transformed the design process altogether. Meanwhile, as technology evolves, it is also opening up new and innovative trends in different sectors.