Flexible PCBs are revolutionising wearable devices by offering unmatched adaptability and durability. In this article, we’ll investigate how these advanced circuits improve performance, making our gadgets more reliable and efficient. OurPCB is one of the top PCB manufacturing organisations directly working towards these concepts and much more. To find why flexible PCBs are the backbone of the next generation of wearables, visit Ourpcb’s flexible PCB manufacturer page.

Understanding Wearable Technology

Wearable technology integrates advanced electronics into everyday accessories. It’s revolutionising healthcare, fitness, and daily life by providing real-time monitoring and feedback.

The Role of PCBs in Wearable Devices

Printed Circuit Boards (PCBs) form the backbone of wearable devices. They connect and support electronic components, ensuring seamless operation. In wearables, flexible PCBs improve device performance in several ways.

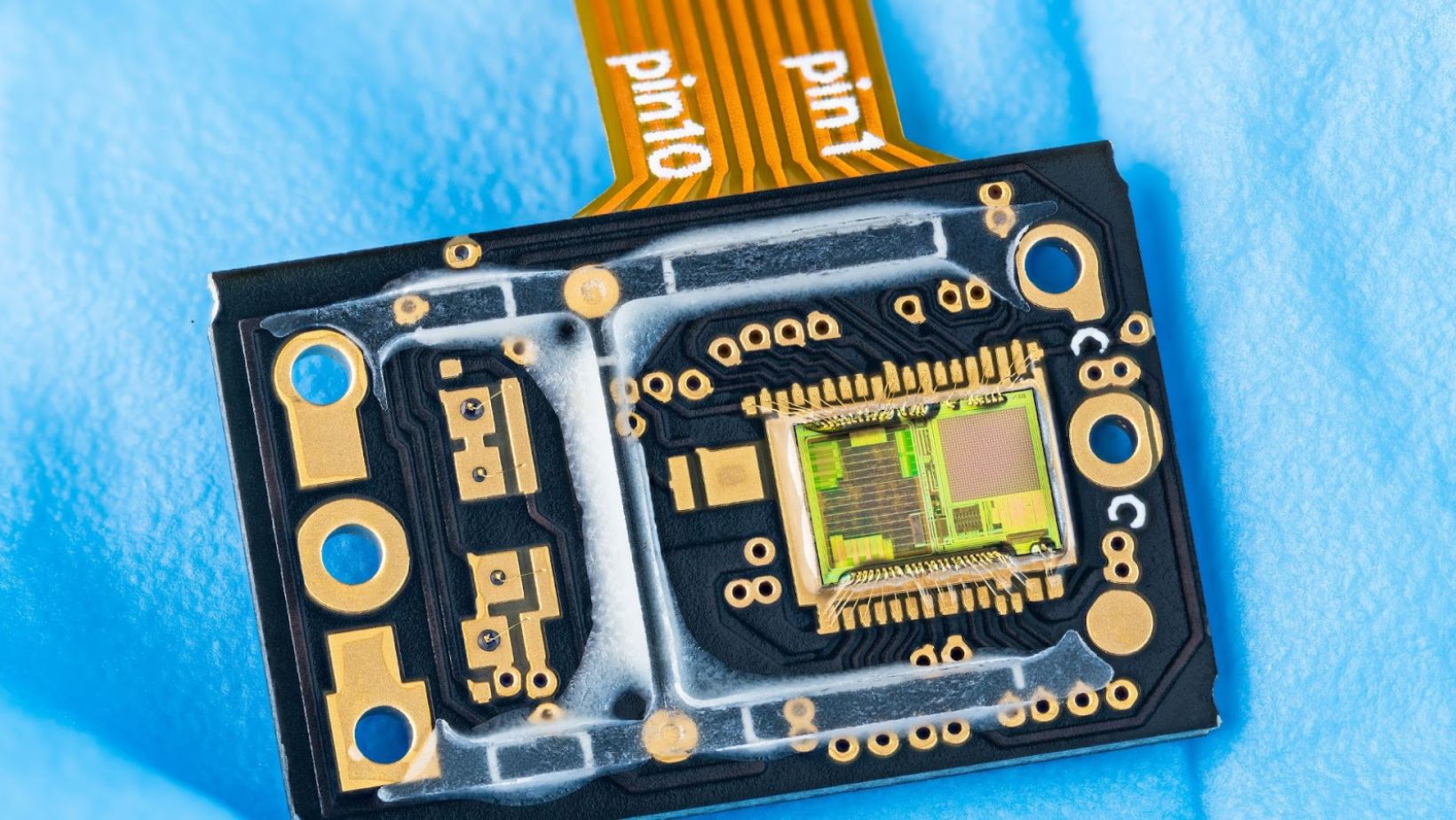

What Are Flexible PCBs?

Flexible PCBs (Printed Circuit Boards) are crucial in modern wearable devices due to their adaptability and compact form factor. These PCBs provide unparalleled design flexibility, making them essential in integrating technology within wearable gadgets.

Key Characteristics of Flexible PCBs

Flexible PCBs offer several key characteristics that improve their functionality in wearables:

- Flexibility and Adaptability: These PCBs can bend, twist, and fold without compromising performance, allowing seamless integration into small, irregularly shaped devices.

- Lightweight Construction: Made from materials like polyimide, flexible PCBs reduce overall device weight, essential for maintaining user comfort in wearables.

- Durability: Resistant to mechanical stress and harsh environments, ensuring longevity and consistent performance in active usage conditions.

- High-Density Interconnect (HDI): Enables compact and complex circuit designs, integrating multiple functions within limited space.

- Efficient Heat Dissipation: Effective thermal management helps in maintaining optimal performance levels and prolongs the lifespan of sensitive components.

These characteristics make flexible PCBs indispensable in developing advanced, reliable wearable technology.

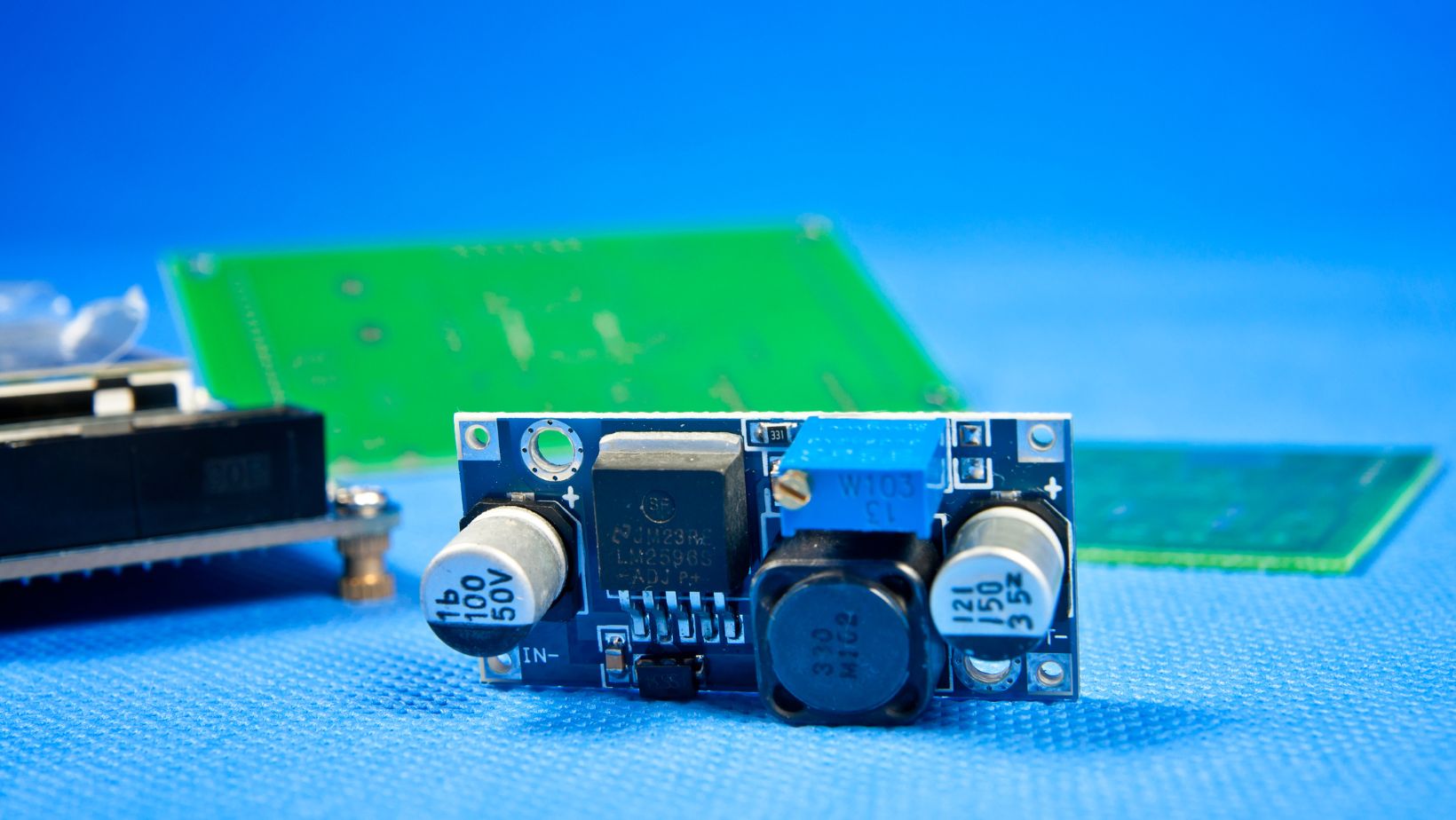

Enhancements Brought by Flexible PCBs

Flexible PCBs offer significant advantages in wearable technology. These enhancements boost device performance and user experience.

Increased Durability and Comfort

Flexible PCBs increase the durability of wearable devices. These PCBs can bend and withstand daily movements, reducing the risk of damage. This flexibility ensures reliable performance in various conditions. Additionally, their lightweight design enhances comfort, making wearables less intrusive for users. For example, fitness trackers and smartwatches benefit from these attributes, improving the overall user experience.

Improved Connectivity and Signal Integrity

Flexible PCBs improve connectivity and signal integrity. They support high-density interconnects (HDI), allowing for more compact and efficient circuit designs. This enhancement reduces signal loss and improves transmission quality.

Wearable devices, such as health monitors and smart clothing, rely on these characteristics to provide accurate real-time data. Proper signal integrity ensures that users receive reliable information, enhancing the trust and utility of the devices.

Flexible PCBs play a critical role in advancing wearable technology by improving durability, comfort, and connectivity. These enhancements make devices more reliable and user-friendly, driving innovation in the industry.

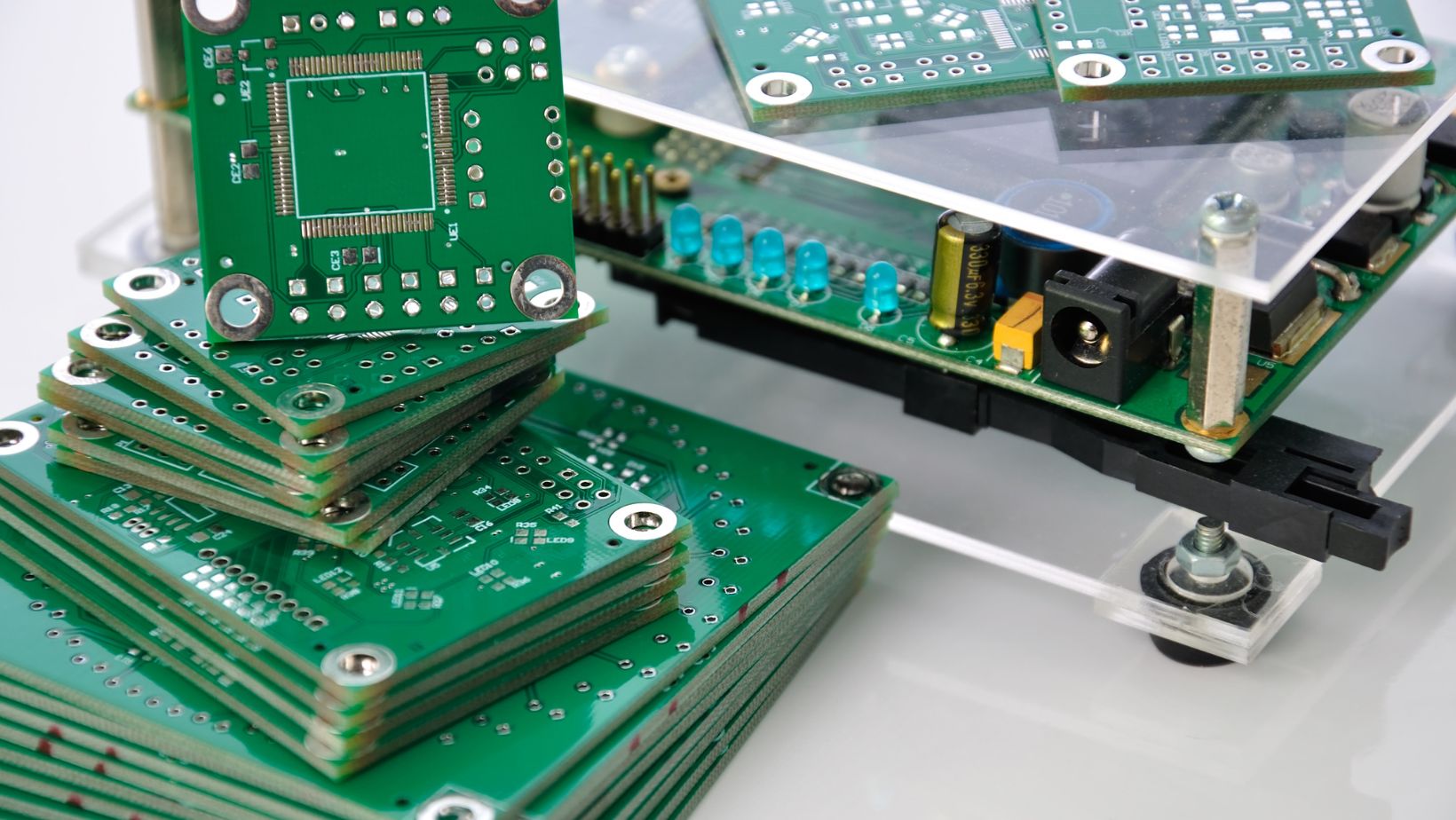

Comparing Flexible and Rigid PCBs in Wearables

Wearable technology integrates flexible and rigid PCBs, but each shows distinct performance characteristics. Flexible PCBs improve flexibility, while rigid PCBs provide structural support.

Design Flexibility and Fit

Flexible PCBs conform to various shapes, fitting seamlessly into complex designs. Their thin, bendable nature allows integration into curved and irregular surfaces, common in smartwatches and fitness trackers. This flexibility improves user comfort as the device molds to body contours, minimising discomfort during prolonged use.

Rigid PCBs, however, are best for straightforward designs where structural integrity matters. These PCBs work well in flat, spacious components but lack the adaptability to fit into compact, ergonomic wearables. Their rigidity can hinder comfort, making them less suitable for devices worn continuously.

Impact on Device Lifespan and Reliability

Flexible PCBs withstand constant movement without compromising functionality. This resilience reduces the risk of connection failures, which is crucial for wearables exposed to daily activities. Their design absorbs stress, extending device lifespan and maintaining reliable performance over time.

Rigid PCBs, while durable in static conditions, don’t fare well under physical stress. Their inability to bend increases the likelihood of cracks and breakages in wearable devices. Recurrent stress weakens connections, leading to device malfunctions. Consequently, they offer less reliability in wearables requiring continuous movement.

By understanding these differences, we can optimise wearable devices, ensuring they provide comfort, durability, and reliable performance. Flexible PCBs significantly improve these aspects, making them a superior choice for most wearable technology applications.

Future Aspect

Flexible PCBs are undeniably transforming wearable technology. Their adaptability and durability significantly boost device performance and user comfort. Industry giants like Apple and Samsung are leveraging these advantages to create more efficient and user-friendly wearables. As flexible PCBs continue to evolve, we can expect even more innovative applications in the wearable tech space. Embracing this technology is crucial for staying ahead in the rapidly advancing world of wearable devices.